Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-01-13 Origin: Site

The optimal choice between a 5-axis Vertical Machining Center (VMC) and a 5-axis Horizontal Machining Center (HMC) hinges entirely on your specific production demands. Making an informed decision requires a clear understanding of their distinct characteristics and how they align with your manufacturing goals. When selecting the right 5-axis CNC machining center for your operations, consider factors such as chip evacuation, thermal stability, and overall machine rigidity. Your specific part characteristics and production volume will guide this critical decision.

Choose a Vertical Machining Center (VMC) for smaller, precise parts. VMCs are good for prototyping or low-volume work.

Select a Horizontal Machining Center (HMC) for large, heavy parts. HMCs are best for high-volume production and automation.

HMCs remove chips better than VMCs. This helps tools last longer and makes parts look better.

VMCs cost less to buy at first. HMCs cost more but can save money over time with higher production.

Think about your part size, how many parts you need, and your budget. This helps you pick the right machine.

You need to grasp the core differences between vertical and horizontal configurations to make an informed decision. Both types offer five axes of movement, allowing you to machine complex parts in a single setup. This capability significantly reduces setup times and improves accuracy.

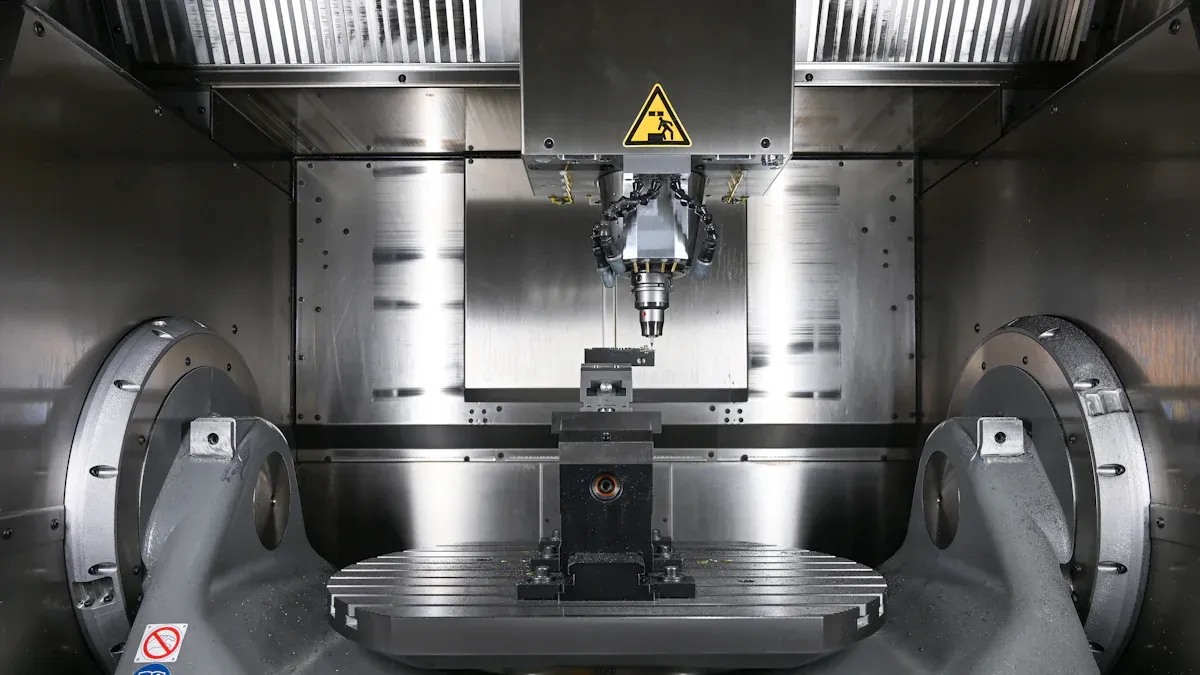

A 5-axis Vertical Machining Center (VMC) features a spindle that operates vertically. This means the cutting tool approaches the workpiece from above. Typically, the VMC achieves its five axes of motion through a combination of linear axes (X, Y, Z) and two rotary axes. These rotary axes often involve a tilting and rotating table where you mount the workpiece. This setup allows the tool to reach various angles on the part without re-fixturing. You will find VMCs are generally more common and often serve as an entry point into 5-axis machining due to their familiar setup and often lower initial cost. They are excellent for parts requiring access from the top or sides.

A 5-axis Horizontal Machining Center (HMC) distinguishes itself with a spindle that operates horizontally. The cutting tool approaches the workpiece from the side. Like VMCs, HMCs also incorporate five axes of motion. These usually include the three linear axes (X, Y, Z) and two rotary axes, often provided by a rotary table that can also tilt or index. This configuration allows you to machine multiple faces of a part in one clamping. HMCs are known for their robust construction and efficient chip evacuation, which we will discuss further. When you consider a 5-axis CNC machining center for heavy-duty or high-volume production, an HMC often presents a compelling option.

The direction your machine's spindle points significantly impacts how you access the workpiece and manage your machining process. This fundamental difference between VMCs and HMCs dictates many operational advantages. You must consider how each orientation aligns with your part geometry and production workflow.

A vertical spindle offers you direct top-down access to your workpiece. This configuration provides excellent visibility of the cutting action. You can easily monitor the machining process and make adjustments. Setting up fixtures and loading parts often feels more intuitive on a VMC. You typically load parts from the top, which simplifies fixturing for many common components. For parts requiring access primarily from one or two faces, a vertical spindle machine offers a straightforward and efficient solution. You also find VMCs generally require less floor space for the machine itself, making them suitable for shops with limited area.

A horizontal spindle presents distinct benefits, especially for complex or heavy parts. You gain superior chip evacuation due to gravity. Chips fall away from the cutting zone naturally, preventing re-cutting and extending tool life. This improves surface finish and reduces heat buildup. Horizontal machines often feature robust designs, providing you with enhanced rigidity for heavier cuts and higher material removal rates. You can also integrate pallet changer systems more effectively with HMCs. This allows you to load a new workpiece on one pallet while the machine processes another. This capability significantly boosts your productivity and enables continuous operation.

Effective chip management significantly impacts your machining process. It directly affects tool life, surface finish, and overall productivity. You must consider how each machine type handles the removal of metal chips from the cutting zone.

You face specific challenges with chip evacuation on a Vertical Machining Center. Gravity works against you. Chips tend to accumulate on the workpiece and in the cutting area. This accumulation can lead to several problems. You might experience re-cutting of chips, which dulls your tools faster. This reduces tool life and increases your operating costs. Chip buildup also compromises surface finish quality. It can even cause heat buildup, affecting part accuracy. You often rely on high-pressure coolant or air blasts to clear chips effectively. This requires careful programming and can sometimes be less efficient for deep pockets or complex geometries.

A Horizontal Machining Center offers you superior chip evacuation. Gravity becomes your ally. Chips naturally fall away from the cutting zone and into the machine's chip conveyor. This keeps the cutting area clean and clear. A clean cutting zone provides several advantages. You achieve longer tool life because tools do not re-cut chips. This also results in a better surface finish on your parts. Reduced chip interference minimizes heat generation, which helps maintain dimensional accuracy. This efficient chip removal contributes to higher material removal rates and more consistent machining processes. You can run your HMC for extended periods with less intervention for chip clearing.

The size, weight, and complexity of your parts heavily influence your machine choice. You must match the machine's capabilities to your specific workpiece requirements. This ensures efficient and accurate production.

You often choose a VMC for smaller, more intricate parts. These machines excel at high-precision work. You can easily access the workpiece from the top. This makes setup and inspection straightforward. VMCs are ideal for components requiring fine details and tight tolerances. Their compact design also suits shops with limited space. You will find VMCs very effective for prototyping or small batch production of complex, smaller items.

You should consider an HMC for larger, heavier workpieces. HMCs have robust frames. These frames provide enhanced rigidity and stability. This is essential for machining large, heavy parts. The horizontal spindle orientation offers stability and accuracy during heavy cuts. Their design allows for easier chip removal. This is crucial for heavy-duty metal parts. HMCs also offer multi-axis capabilities, including 5-axis. This enables handling complex geometries and multi-sided machining on large components. You can process larger workpieces efficiently on an HMC. This makes them suitable for automotive blocks or aerospace components.

Both VMCs and HMCs can handle complex geometries. A 5-axis CNC machining center provides the necessary rotational and linear movements. This allows you to machine intricate features in a single setup. For parts with deep pockets or internal features, the choice often comes down to chip evacuation and part size. VMCs might require more effort to clear chips from deep features. HMCs naturally evacuate chips, which benefits complex internal machining. You must evaluate your part's specific geometric challenges. This helps you determine which machine offers the most efficient solution.

Your choice of machine significantly impacts your overall productivity and potential for automation. You must consider how each machine type handles setup, part loading, and unattended operation. This directly affects your throughput and labor costs.

You often find VMCs require more manual intervention for setup and part changeovers. You typically load one workpiece at a time onto the machine table. This process demands operator presence. Tool changes also interrupt the machining cycle. If you run small batches or frequently change parts, these manual steps can accumulate. They reduce your overall machine uptime. You must account for this idle time when you calculate your production efficiency.

HMCs excel in automation and continuous operation. You can integrate them with sophisticated pallet changer systems. These systems allow you to load a new workpiece onto one pallet while the machine processes a part on another. This capability significantly reduces non-cutting time. You achieve higher machine utilization. Many HMCs also feature large tool magazines. This supports longer production runs without operator intervention. You can easily integrate robotic loading and unloading systems with HMCs. This further enhances automation.

Both VMCs and HMCs can support lights-out manufacturing, but HMCs offer distinct advantages. You can run HMCs for extended periods without human supervision. Their efficient chip evacuation and robust design contribute to this. Pallet systems allow you to queue up many hours of work. This maximizes your machine's uptime. You can produce parts overnight or during weekends. This significantly boosts your overall throughput. You need reliable tool monitoring and breakage detection systems for successful lights-out operation. OTURN MACHINERY's high-speed CNC machining centers, like the GM series, offer robust structures and advanced cooling systems. These features support stable, long-term operation essential for unattended production.

You demand high accuracy and precision from your machining operations. The inherent rigidity and vibration control of your chosen machine directly impact these critical factors. You must understand how each machine type manages these elements to achieve optimal part quality.

You will find modern VMCs offer significant rigidity. Their design typically features a robust column and base structure. This provides a solid foundation for the vertical spindle. You often see heavy cast-iron construction. This material effectively dampens vibrations. The machine's overall mass contributes to its stability. However, the vertical orientation can sometimes introduce cantilevered forces, especially when the spindle extends far from the column. You must consider the machine's specific design and construction. This ensures it meets your precision requirements for various cutting conditions.

HMCs inherently offer superior stability and precision, especially for heavy cutting. The horizontal spindle configuration places the cutting forces closer to the machine's bed. This creates a more stable cutting environment. You benefit from a lower center of gravity. This design minimizes vibration during aggressive material removal. The robust construction of HMCs, often with large, heavy bases, further enhances their rigidity. This stability allows you to achieve tighter tolerances and better surface finishes. You can perform heavy cuts with greater confidence. This leads to consistent part quality over long production runs.

You must carefully consider the physical space your machining center occupies. This directly impacts your shop floor layout and overall operational efficiency. The machine's footprint determines how you arrange other equipment and manage workflow.

You will find VMCs generally require less floor space. Their vertical design means they often have a smaller footprint compared to HMCs. This makes them ideal for shops with limited square footage. You typically load workpieces from the top or front. This allows you to place VMCs closer to walls or other machines. However, you still need to allocate space for operator access and maintenance. You also need room for chip conveyors and coolant systems. These components can extend beyond the machine's main body. Consider the overall dimensions, including any auxiliary equipment, when planning your layout.

HMCs typically demand a larger footprint. Their horizontal spindle configuration and often integrated pallet changer systems contribute to this. You need ample space around the machine for pallet loading and unloading. This is especially true if you plan for automated systems or robotic integration. The machine's length can be substantial. This accommodates the horizontal travel of the spindle and the workpiece. While HMCs offer high productivity, you must ensure your facility can accommodate their larger physical presence. Plan for sufficient clearance for maintenance access and material handling. This ensures smooth operation and future expansion possibilities.

You must carefully evaluate the financial aspects of your machine tool purchase. This includes both the initial investment and long-term operating expenses. Your choice between a VMC and an HMC significantly impacts your budget and potential return on investment (ROI).

You will find VMCs generally require a lower initial investment. This makes them an attractive option for many businesses. Their simpler design often translates to lower purchase prices. Operating costs for VMCs can also be manageable. However, you must consider potential inefficiencies. Manual setups and slower chip evacuation can increase labor costs and reduce tool life. These factors can impact your overall cost-per-part over time.

HMCs represent a more substantial initial investment. They are generally far more expensive than VMCs. This is due to their larger size and high rigidity requirements. You can expect an HMC to cost 2-3 times more than a comparable VMC.

| Feature | VMC | HMC |

|---|---|---|

| Initial Cost | Lower | Higher |

| Cost Multiple | 1x | 2-3x |

Despite this higher upfront cost, HMCs offer significant long-term benefits. They allow for improved productivity and lower labor costs. You can load a new workpiece onto a pallet while the machine cuts another part. This results in less idle spindle time. It also gives your employees more flexibility to work on other tasks. This continuous operation contributes to a better ROI. For the right applications, such as high-volume or complex part production, the incredible productivity of an HMC can lead to a lower cost-per-part. You can achieve a faster return on investment over the machine's lifetime, despite its higher initial cost.

You need to match the right machine to your production needs. This ensures efficiency and profitability. Understanding the ideal applications for each 5-axis CNC machining center helps you make the best choice.

You should choose a 5-axis VMC for precision parts and complex geometries that benefit from top-down access. VMCs are excellent for smaller components. They handle intricate details well. For example, you can use a 5-axis VMC for creating complex molds. The LASERTEC 210 Shape, a 5-axis machine, is designed for laser-machining applications. It is specifically noted for machining injection mould forms. This machine can integrate its laser head into its milling spindle. This highlights its versatility for complex tasks.

VMCs also excel at prototyping and low-volume production. You can quickly set up and change over parts. This makes them flexible for varied jobs. Consider a VMC for parts like:

Impellers: This component has a complex curved surface and closely located blades. You can process it on a five-axis CNC machine. Its intricate geometry needs specific tool trajectories and optimal cutting modes. Standard CAM systems are often insufficient for its production.

Medical implants

Aerospace components with intricate features

Tool and die making

You will find VMCs are a cost-effective entry point into 5-axis machining. They offer high accuracy for many applications.

You should choose a 5-axis HMC for high-volume production and heavy-duty machining. HMCs are perfect for larger, heavier workpieces. Their robust construction handles aggressive material removal rates. You benefit from superior chip evacuation. This leads to longer tool life and better surface finishes.

HMCs shine in automated environments. You can integrate them with pallet changer systems. This allows for continuous, lights-out manufacturing. You load new parts while the machine works. This significantly boosts your throughput. Consider an HMC for:

Automotive engine blocks and transmission cases

Aerospace structural components

Large industrial machinery parts

Components requiring multi-sided machining in a single setup

You will achieve higher machine utilization with an HMC. This makes them ideal for industries demanding consistent, high-volume output. Their stability ensures precision even during demanding operations.

Selecting the ideal 5-axis CNC machining center for your operations requires careful consideration. You must align the machine's capabilities with your specific manufacturing needs. This strategic decision impacts your productivity, cost-efficiency, and overall success.

You must thoroughly analyze the parts you intend to machine. Consider their size, weight, and material. Smaller, lighter parts with intricate details often suit a Vertical Machining Center (VMC). These machines provide excellent visibility and access for precision work. For larger, heavier components that require aggressive material removal, a Horizontal Machining Center (HMC) offers superior rigidity and stability.

Evaluate the complexity of your part geometries. Parts with many features on multiple sides might benefit from the multi-sided access an HMC provides. This reduces the need for re-fixturing. If your parts primarily require machining from the top or a few sides, a VMC can be highly efficient. Also, consider the required surface finish and tolerance. Both machine types can achieve high precision, but the inherent stability of an HMC can be advantageous for extremely tight tolerances under heavy cutting conditions.

Your production volume and typical batch sizes significantly influence your machine choice. This factor directly impacts your throughput and operational efficiency.

For low-to-mid volume production, prototyping, or job shops with varied tasks, a VMC often proves to be a cost-effective and versatile solution. VMCs are highly adaptable. They excel at producing parts requiring machining on one or two faces. However, VMCs generally require more time for setup. Work cannot proceed on other parts simultaneously. This means the machine must stop for each part change. This leads to more downtime and lower throughput in high-volume production environments.

Conversely, HMCs are production powerhouses. They are ideal for high-volume, complex, and automated manufacturing. Most HMCs allow you to set up new jobs while another part is being cut. This is possible thanks to a rotating machine table or pallet changer systems. Once a part finishes, it rotates out. An uncut part then takes its place. This allows immediate continuation of machining. You can remove the completed part while the machine runs. This continuous operation is highly beneficial for high-volume production. HMCs often come equipped with pallet-changing systems and large tool magazines. Tombstone fixturing on HMCs holds multiple parts or allows multi-sided access. Automatic pallet changers (APCs) enable continuous cutting. They swap finished parts with new ones in seconds. This minimizes spindle downtime. Operators can load or unload parts on an idle pallet while the machine runs.

Here is a quick comparison:

| Feature | Vertical Machining Center (VMC) | Horizontal Machining Center (HMC) |

|---|---|---|

| Productivity | Ideal for low-to-mid volume, prototyping | Ideal for high-volume, automated production |

| Setup Complexity | Simple and fast for single-sided work | More complex (tombstones) but fewer setups needed |

You should think beyond your current production needs. Consider your long-term business goals and potential future demands. Will your part designs become more complex? Do you anticipate an increase in production volume?

Investing in a machine that offers flexibility can save you money in the long run. A VMC might be sufficient for current needs. However, if you foresee a rapid increase in volume or a shift towards more complex, multi-sided parts, an HMC could be a more scalable solution. Its automation capabilities can easily integrate into future production lines. Evaluate the machine's ability to adapt to new materials or part types. A robust 5-axis CNC machining center provides versatility. This allows you to take on a wider range of projects. Choose a machine that supports your growth trajectory. This ensures your investment remains valuable for years to come.

You must carefully analyze your budget and expected return on investment (ROI). This financial assessment guides your decision between a VMC and an HMC. You need to consider both the initial purchase price and the long-term operational costs.

A Vertical Machining Center (VMC) generally requires a lower initial investment. This makes VMCs an attractive option for businesses with tighter budgets. You can acquire a VMC for significantly less capital outlay compared to an HMC. However, you must also factor in the operating costs. VMCs often involve more manual intervention for setups and part changeovers. This can increase labor costs. Their chip management challenges might also lead to more frequent tool changes. These factors can impact your overall cost per part. For lower production volumes or specialized, high-precision tasks, a VMC often provides a quicker ROI due to its lower entry cost.

A Horizontal Machining Center (HMC) demands a higher initial investment. HMCs are typically more expensive to purchase. Their robust construction, advanced automation features, and integrated pallet systems contribute to this higher price tag. You might see an HMC costing two to three times more than a comparable VMC. Despite this higher upfront cost, HMCs offer substantial long-term ROI, especially for high-volume production.

Consider the following for HMC ROI:

Increased Throughput: HMCs allow for continuous operation. You can load new parts while the machine processes others. This significantly reduces spindle downtime.

Lower Labor Costs: Automation features, like pallet changers, reduce the need for constant operator presence. You can achieve lights-out manufacturing. This frees up your skilled labor for other tasks.

Consistent Quality: Superior rigidity and chip evacuation lead to more consistent part quality. This reduces scrap rates and rework.

Extended Tool Life: Efficient chip removal prevents re-cutting. This extends the life of your cutting tools. It lowers your consumable costs.

You should calculate the cost per part for both machine types. Include all relevant factors: machine depreciation, labor, tooling, maintenance, and energy consumption. For high-volume production, the incredible productivity and efficiency of an HMC often lead to a lower cost per part over the machine's lifespan. This results in a faster and more substantial return on your investment, despite the higher initial expenditure. You must align your investment with your production goals and financial capabilities.

The "best" 5-axis CNC machining center is not a universal solution. Instead, you must select the machine that perfectly aligns with your unique production goals and operational constraints. A thorough evaluation of VMC and HMC advantages and disadvantages against your specific needs is crucial. This careful assessment ensures you make an informed decision. Ultimately, this strategic investment will significantly enhance efficiency, improve product quality, and boost profitability in your manufacturing operations.

The main difference lies in the spindle orientation. A 5-axis VMC has a vertical spindle, approaching the workpiece from above. A 5-axis HMC features a horizontal spindle, accessing the workpiece from the side. This fundamental difference impacts workpiece access and chip management.

You will find a 5-axis horizontal CNC machining center provides superior chip evacuation. Gravity naturally pulls chips away from the cutting zone. This prevents re-cutting and extends tool life. VMCs often require high-pressure coolant to clear chips effectively.

Yes, you can achieve lights-out manufacturing with both. However, HMCs offer distinct advantages. Their efficient chip evacuation and robust design support longer unattended runs. Pallet systems on HMCs allow continuous operation, maximizing machine uptime without human intervention.

You will generally find a 5-axis VMC requires a lower initial investment. Their simpler design often translates to a more accessible purchase price. HMCs represent a more substantial upfront cost due to their larger size and advanced automation features.